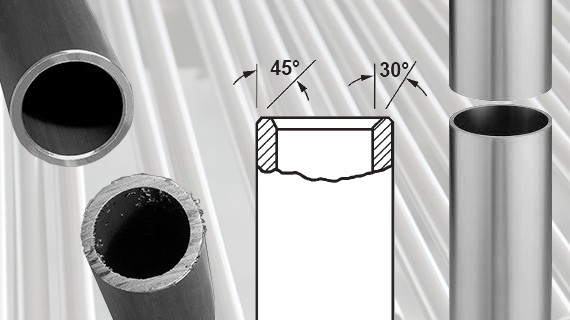

You’ll need to square and deburr tube / pipe prior to performing beading or flaring end finishing. Tube ends ends may be rough and uneven from cutting. Squaring creates a flat, perpendicular surface on the end and deburring ensures there are no burrs to interfere in joining or disrupt any subsequent forming process. Even if you’re not flaring or beading, a faced and squared end surface makes tubing easier to align.

PHI end finishing machines and tooling meet these needs. In almost every case, the same end finishing machine can be used to perform the required squaring, facing, and deburring of the cut end of a tube before a flare or bead is formed. With use of a squaring and deburring head and blades, tubing and pipe can be squared and the inside and outside faces deburred and chamfered.