PHI Tube End-Finishing Machines, Models 2C, 2CP, 2CPV, 3CPV and 8CPV, form a family of machines for preparing the ends of tube or pipe for joining with other tube or pipe sections, valves, T-joints, or machinery.

Capabilities of PHI Tube and Pipe End-Finishing Machines

Using PHI’s tube end-finishing machines, tube and pipe ends can be prepared with a bead or flare, or simply deburred and squared. Each machine is capable of performing all of these cold forming functions with precision and reliable repeatability; a change of tooling is all that is required to switch from one function to another.

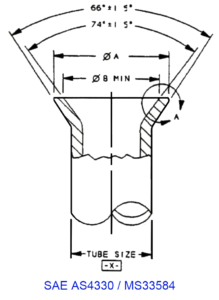

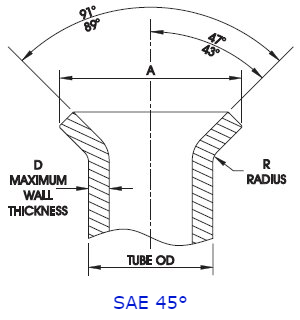

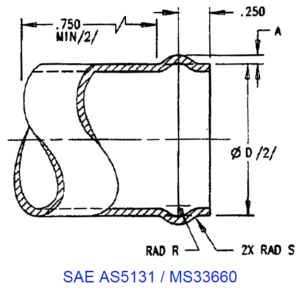

Specifications met: Single flaring to SAE 37° and SAE 45° including SAE AS4330 (formerly military spec MS33584); Beading to SAE AS5131 (formerly MS33660). Contact us regarding JIC, AN, ASME, or other standards or custom angles.

Model 2C, 2CP, and 2CPV

These 2CX models are designed for smaller-diameter tubes and pipes — 0.25 to 2 inches.

Model 2C features manual clamping for easy-to-form materials and low production requirements. Model 2CP has air-cylinder clamping for higher production rates and more difficult-to-form materials. Both models have two-speed spindles, allowing you to choose the most efficient speed for the function you are performing.

The 2CPV capacities are the same as the 2CP with the addition of a variable-speed drive (0-2000 RPM) with a 3/4 HP motor and digital RPM readout / tachometer. The variable-speed motor allows the operator to select an optimal spindle speed for the material and end forming method, providing for additional control of output precision and extending blade life when deburring harder materials such as stainless steel and titanium.

2CV model is available on request for those who need the greater control of variable-speed drive but don’t want to (or can’t) make available air supply for pneumatic clamping.

Options for all 2CX machines include: stand with tool cabinet, work light

Model 3CPV

The Model 3CPV extends the range of the PHI end finishing machines to include tubes and pipes with outside diameters up to 3 inches and ability to form tubing with larger wall thicknesses.

As in the case of the other PHI models, flares are formed to standard 37° and 45° angles, meeting MS33584 and SAE 54330 specifications. Beads are formed within the tight specifications called for in Military Specification MS33660 / SAE AS 5131.

Features of the Model 3CPV include pneumatic clamping, cabinet stand with tooling shelf, and variable-speed motor. The variable-speed motor allows the operator to select an optimal spindle speed for the material and end forming method, providing for additional control of output precision and extending blade life when deburring harder materials such as stainless steel and titanium.

Options for the 3CPV include: beading up to 3″, automatic beading function, automatic flaring function, digital tachometer, moveable base, work light.

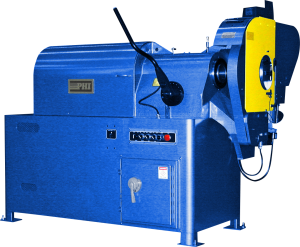

Model 8CPV

Model 8CPV is the largest in the family of PHI end finishing machines and can be used to flare, bead, deburr, and square tubes or pipes with outside diameters up to 8 inches.

An air cylinder with heavy-duty linkage holds the tube or pipe firmly in place during each operation, preventing slippage and ensuring that all forming is done within appropriate specifications. Model 8CPV also features a variable-speed drive for efficient operation regardless of material or wall thickness. Hard materials such as stainless steel can be deburred at slower speeds, for example, without undue wear of the blades.

| 2C | 2CP | 2CPV | 3CPV | 8CPV | |

|---|---|---|---|---|---|

| Squaring & Deburring | • Annealed Ferrous: 0.25 to 2 in OD • Stainless Steel: 0.25 to 2 in OD • Non-ferrous: 0.25 to 2 in OD | • Annealed Ferrous: 0.25 to 2 in OD • Stainless Steel: 0.25 to 2 in OD • Non-ferrous: 0.25 to 2 in OD | • Annealed Ferrous: 0.25 to 2 in OD • Stainless Steel: 0.25 to 2 in OD • Non-ferrous: 0.25 to 2 in OD | • Annealed Ferrous: 0.25 to 3 in OD • Stainless Steel: 0.25 to 3 in OD • Non-ferrous: 0.25 to 3 in OD | • Annealed Ferrous: 1.25 to 8 in OD • Stainless Steel: 1.25 to 8 in OD • Non-ferrous: 1.25 to 8 in OD |

| Flaring | • Annealed Ferrous: 0.25 to 2 in OD x 0.049 WT • Stainless Steel: 0.25 to 2 in OD x 0.049 WT • Non-ferrous: 0.25 to 2 in OD x 0.065 WT | • Annealed Ferrous: 0.25 to 2 in OD x 0.049 WT • Stainless Steel: 0.25 to 2 in OD x 0.049 WT • Non-ferrous: 0.25 to 2 in OD x 0.065 WT | • Annealed Ferrous: 0.25 to 2 in OD x 0.049 WT • Stainless Steel: 0.25 to 2 in OD x 0.049 WT • Non-ferrous: 0.25 to 2 in OD x 0.065 WT | • Annealed Ferrous: 0.25 to 3 in OD x 0.125 WT • Stainless Steel: 0.25 to 3 in OD x 0.125 WT • Non-ferrous: 0.25 to 3 in OD x 0.125 WT | • Annealed Ferrous: 1.25 to 8 in OD x 0.125 WT • Stainless Steel: 1.25 to 8 in OD x 0.125 WT • Non-ferrous: 1.25 to 8 in OD x 0.125 WT |

| Beading | • Annealed Ferrous: 0.25 to 0.375 in OD x 0.035 WT; 0.5 to 1.5 in OD x 0.049 WT • Stainless Steel: 0.5 to 1.5 in OD x 0.049 WT • Non-ferrous: 0.25 to 0.375 in OD x 0.035 WT; 0.5 to 1.5 in OD x 0.065 WT | • Annealed Ferrous: 0.25 to 0.375 in OD x 0.035 WT; 0.5 to 1.5 in OD x 0.049 WT • Stainless Steel: 0.5 to 1.5 in OD x 0.049 WT • Non-ferrous: 0.25 to 0.375 in OD x 0.035 WT; 0.5 to 1.5 in OD x 0.065 WT | • Annealed Ferrous: 0.25 to 0.375 in OD x 0.035 WT; 0.5 to 1.5 in OD x 0.049 WT • Stainless Steel: 0.5 to 1.5 in OD x 0.049 WT • Non-ferrous: 0.25 to 0.375 in OD x 0.035 WT; 0.5 to 1.5 in OD x 0.065 WT | • Annealed Ferrous: 0.25 to 0.375 in OD x 0.035 WT; 0.5 to 1.5 in OD x 0.065 WT • Stainless Steel: 0.5 to 1.5 OD x 0.065 WT • Non-ferrous: 0.25 to 0.375 in OD x 0.035 WT; 0.5 to 1.5 in OD x 0.065 WT • Up to 3 in OD available - see options | • Annealed Ferrous: 1.25 to 8 in OD x 0.065 WT • Stainless Steel: 1.25 to 8 in OD x 0.065 WT • Non-ferrous: 1.25 to 8 in OD x 0.065 WT |

| Spindle Speed | Two Speed Spindle: 500 RPM and 1500 RPM | Two Speed Spindle: 500 RPM and 1500 RPM | Variable Speed Spindle: 50 RPM to 1800 RPM | Variable Speed Spindle: 300 to 1750 RPM | Variable Speed Spindle: 59 to 550 RPM |

| Motor | AC, 0.5 HP | AC, 0.5 HP | DC, 0.75 HP | AC, 3.0 HP | AC, 7.5 HP |

| Jaws Closing Method | Manual, lever operated | Automatic air cylinder clamping. Air Supply: 1-1/2 CFM at 75-100 PSI | Automatic air cylinder clamping. Air Supply: 1-1/2 CFM at 75-100 PSI | Automatic jaw closing with "Safe Protec Jaws." Air cylinder clamping Air Supply: 1-1/2 CFM at 75-100 PSI | Automatic jaw closing with "Safe Protec Jaws." Air cylinder clamping Air Supply: 1-1/2 CFM at 75-100 PSI |

| Dimensions L x W x H | 28 x 18 x 15 in | 28 x 18 x 15 in | 28 x 18 x 15 in | 36 x 26 x 46 in | 77 x 41 x 55 in |

| Weight | 300 lb | 350 lb | 350 lb | 750 lb | 2200 lb |

| Options | Cabinet Stand | Cabinet Stand | Cabinet Stand | • Beading Assembly, Manual, 0.25 to 3.0 in TOD • Beading Assembly, Automatic, 0.625 to 3.0 in TOD • Moveable Base • Digital Tachometer • Work Light | • 108399 - Die Adapter Assy. FOR 0.875 to 3.0 in TOD • 103645 - Spindle Adapter Assy. for 2.0 in TOD and UNDER • 104454 - Spindle Adaptor (HD) for 2.0 in TOD and UNDER • 105018 - Flare Center Assy. for 1.5 to 3.0 in TOD • 105338 - Flare Center Assy. for 2.5 to 6.0 in TOD • 104998 - Flare Center Assy. for 4.0 to 8.0 in TOD |

| More Info | |||||

| * European models — CE Conformity for EU — available, e.g. Models: 2CPV-E, 3CPV-E. Contact us for more information. | |||||

About Squaring, Deburring, & Flaring

Flared joints form liquid-tight, air-tight connections at the ends of tubing or pipe. To obtain an effective, long-lasting seal, each end of the tube or pipe must be formed to the exact shape of the matching flare fittings. Tooling supplied by PHI meets this objective, and in almost every case, the same end finishing machine can be used to perform the required squaring and deburring of the cut end of a tube — before the flare is formed. With use of a squaring and deburring head and blades, tubing and pipe can be squared and the inside and outside faces deburred and chamfered

Typical Applications

Hydraulic systems and fuel lines in the aircraft, automotive, and heating and cooling industries.

About Beading

Beading is a versatile end-finishing technique that can be applied to a variety of industrial applications. In conjunction with an o-ring, for example, beaded joints can be used to interconnect exhaust tubes or low-pressure fuel lines. Beads can also be used to dampen vibration in solid lines or to increase the effectiveness of the seal when a rubber or fabric sleeve is clamped to a metal duct.

Typical Applications

Low-pressure air, exhaust, and liquid systems in the automotive, appliance, and boating fields.

Videos

PHI 2CPV Tube/Pipe Flaring

PHI 3CP Tube/Pipe End Finishing

PHI 3CPV Tube/Pipe Auto-Flare End Finishing

PHI 2CPV Tube/Pipe Square and De-burr End Finishing

PHI 2CPV Tube/Pipe Squaring and Deburring

PHI 2CPV Tube/Pipe Beading

Photos – 2CX Machines

Photos – 3CX Machines

Similar, Older Models: Conrac Leonard Tubemaster Model B, Model C, Model 2B, Model 2C, Model CP, Model 3CP-HD, 3CP-HDF

Tube End Forming Terms: chamfering, deburring, flaring, beading, flanging, swaging, facing, jaws, tube, pipe, shapes, torque, load, capacity, Leonard Tubemaster, 2C NSN 3441-00-528-8629, 2CP NSN 3441-00-528-8629, 2CPV NSN 3441-01-438-1811, 3CPV NSN 3441-00-528-8680, 8CPV NSN 3441-00-210-9754