PHI’s Model DF is a high-production tube and pipe end finishing unit, allowing the production of up to 600 double lap flares per hour. The machine is operated by a single lever which activates the two steps required to form a double flare. No electricity is required. All operations are pneumatically powered.

PHI’s Model DF is a high-production tube and pipe end finishing unit, allowing the production of up to 600 double lap flares per hour. The machine is operated by a single lever which activates the two steps required to form a double flare. No electricity is required. All operations are pneumatically powered.

The Model DF is a double-lap flaring machine which produces a double thickness flare. It will also produce a single-thickness flare and an upset bead.

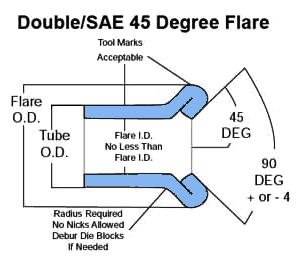

The machine forms double-lap flares to precise 37° and 45° dimensions. Single flares are also done with precision and within specifications — every time. All flares are within the tolerance of SAE 37° and 45°, MS 33583, AND10078/JIC specifications, and upset beading is within the tolerance of specification AND10060, all subject to material hardness and wall thickness limits.

About Double Flaring

Double-lap flares provide added-strength joints which are more resistant to fatigue and provide a better seal than single-thickness flares.

Double-lap flares formed by PHI machinery and tooling are free of cracks and pitmarks. The joint is also designed so that the inside surface of the flare has a larger diameter than the inside diameter of the tube or pipe and, therefore, does not interfere with flow characteristics of the system.

Typical Applications

Thin-wall tubing connections that are subject to shock, vibration, or high internal pressures such as automobile brake lines and critical aircraft hydraulic lines.

Specifications

| Model DF | |

|---|---|

| Capacity - Double Lap Flaring | 1/8 in to 1/2 in OD, annealed ferrous or nonferrous tubing |

| Capacity - Single Flaring | 1/8 in to 3/4 in OD, annealed ferrous or nonferrous tubing |

| Capacity - Beading | 3/16 in to 1/2 in OD, annealed ferrous or nonferrous tubing |

| Operation | Single lever operated, entirely pneumatically powered |

| Air Supply | 75-100 psi air supply required. Air consumption approx. 1-1/2 cfm at 100 psi. No electrical connection. |

| Standard Tooling | For MS and SAE Flare Specifications |

| Dimension | 28 in x 18 in x 42 in (L x W x H) |

| Shipping Weight | 480 lb |

Tooling

See PHI Tube/Pipe End-Finishing Equipment and Tooling Catalog, pages 20-21.

Videos

PHI DF Double-Flare Tube End Former

PHI (Leonard) DF Double-Flare Tube End Former (Demo 1)

PHI Double-Flare Demo 2 – Tube End Former

More DF Machine Photos

Tube End Forming Terms: double flaring, double lap flare, 37 degree, 45 degree, flare punch, upset punch, upset bead, chamfering, deburring, flaring, beading, flanging, swaging, facing, jaws, tube, pipe, shapes, torque, load, capacity, MS33583, MS33584, AS33583, SAE J533, AND10078 / JIC, AND10060, 2C NSN 3441-00-528-8629, 2CP NSN 3441-00-528-8629, 2CPV NSN 3441-01-438-1811, 3CPV NSN 3441-00-528-8680, 8CPV NSN 3441-00-210-9754