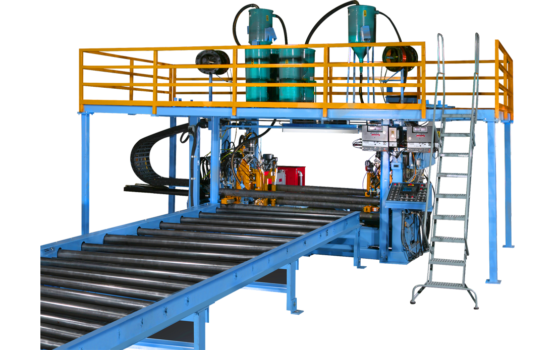

Structural Beam Fabrication System

PHI’s Structural Beam Welding Line is designed to manufacture custom steel beams such as those used in pre-engineered steel buildings, engineered metal buildings, bridges, shipyards, and trailers / semi truck trailers / tractor truck beds.

By manufacturing custom beams, straight or tapered, and with web and flange dimensions not available in standard beams purchased from a steel mill, a building manufacturer can achieve significant savings in steel costs as compared to using conventional I beams purchased from a steel mill.

For Fast Fabrication of Quality “H” Beams

The main characteristic of PHI’s Structural Beam Fabrication System is its ability to produce beams continuously, beam after beam, with minimum down time for changing welding parameters or beam sizes. While actual production capacity will depend on the size and type of beams to be fabricated, typical output is 2,000 tons of steel per month in one eight-hour shift employing only three operators.

PHI Automatic Steel Beam Welder Brochure

Custom steel beam welding for applications like: engineered metal buildings, pre-engineered steel buildings, shipyards, semi truck trailers / tractor truck beds, bridges, and platforms. You can now manufacture custom beams continuously with minimum delays for changing beam sizes or shapes. The PHI Automatic Beam Welder gives your operation higher productivity, on both straight and tapered […]

Read More

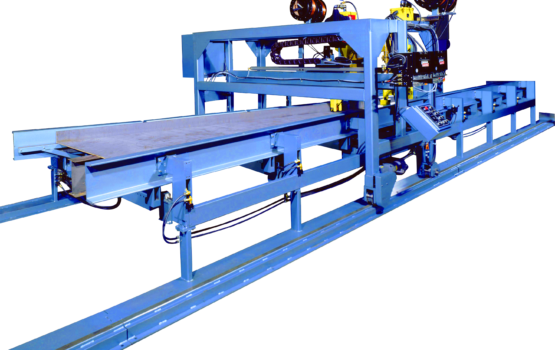

Auxiliary Equipment for Welding Systems

Enhance the speed, ability, and productivity of your PHI Automatic Steel Beam Welding Lines by adding auxiliary equipment. Flange Tilting Device The Flange Tilting Device is used during the manufacturing of “H” beams. Flanges are automatically tilted to a vertical position against magnetic rollers prior to assembly with the web at the tacking fixture. Done […]

Read More

Gantry Welding System The Gantry Welding System from PHI is designed to provide improved productivity over the manual or semi-automatic welding of structural H beams. The welding gantry, with automatic dual heads and wire feeders, can provide a continuous sub-arc weld for the maximum deposit of weld metal at faster travel speeds, reducing operating costs […]

Read More