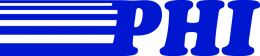

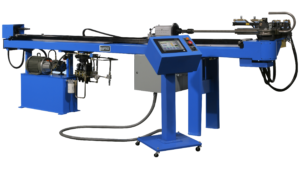

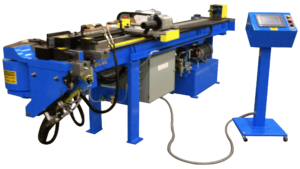

PHI’s synchronized tube bending machines, Models 210, 220, and 233, offer three-axis bending with one powered axis for the degree of bend (DOB). When configured as shown, these 200 series benders provides high-speed production of simple and complex bent tube shapes up to 3 in outside diameter (OD) and pipes up to 2 in IPS.

Configurations range from a slim head and bed profile with spacious underbed clearance to minimize bending interference, a drop-away clamp (Models 220 & 233 only) which speeds production of complex parts by dropping the clamp away from the bend head prior to retracting the clamp and positioning it for the next bend. This eliminates the problem of pipe getting in the way of the clamp and bend die in its retraction cycle. Our modular design – a basic machine with many options – allows each machine to be custom fitted to best meet your needs.

PHI’s user-friendly programmable digital controller is specifically designed for bending and is logically laid out for proper bending sequencing. It has a capacity for 100 programs consisting of 1 to 10 bends per program.

The optional carriage allows mechanical presetting of up to 10 planes of bend (POB) and 10 distance between bends (DBB). When incorporated with the controller, the machine will synchronize and interlock all three positions (POB, DOB and DBB) to ensure correct tube alignment before bending can occur. This ensures easily repeatable bent tube shapes and scrap free production.

- Quality Output: Perfect part duplication, scrap-free production, quality tooling, positive POB stops and DBB stops.

- Labor Savings: Single setup for multiple bend parts.

- Reliable Performance: Heavy-duty construction and extra-large electric motors.

- Performance-Enhancing Features: Precision PHI tooling to help reduce wall thinning and ovality. Synchronized interlock positioning for accurate, scrap-free parts.

| Model 210 | Model 220 | Model 233 | |

|---|---|---|---|

| Torque: | 17,200 lb-in | 52,000 lb-in | 144,575 lb-in |

| Capacity: Max. OD A) Tube B) Pipe | 2" max. OD Examples*: A) 2” (50 mm) OD x 0.035” (0.88 mm) wall thickness x 2D minimum CLR or 1-1/2” (37.5mm) OD x 0.065” (1.63mm) wall thickness x 2D minimum CLR B) 1” (25mm) OD x Schedule 40 x 3D minimum CLR | 2" max. OD Examples*: A) 2” (50 mm) OD x 0.125” (3.17 mm) wall thickness x 2D minimum CLR B) 1-1/2” (37.5 mm) OD x Schedule 40 x 2D minimum CLR | 3" max. OD Examples*: A) 3” (75 mm) OD x 0.188 (4.7 mm) wall thickness x 3D minimum CLR B) 2-1/2” IPS (73 mm) OD x Schedule 80 x 3D minimum CLR |

*Based on material (ASTM A-587 steel or equivalent) with 60,000 psi tensile strength, 35,000 psi (241 MPa) yield, 35% elongation |

|||

| Direction of Bend | Clockwise (Counter-clockwise rotation is available on special order) | Clockwise (Counter-clockwise rotation is available on special order) | Clockwise (Counter-clockwise rotation is available on special order) |

| Center Line Radius (CLR) | 8” (200mm) max. standard, 12” (300mm) optional | 10” (254mm) max. standard | 15” (381mm) max. standard |

| Maximum Bend Arm Movement | 195° | 180° and springback allowance | 195° |

| Maximum Over-Mandrel Tube Length | 10 feet (3.0m) standard, Longer lengths optional | 10 feet (3.0m) standard, Longer lengths optional | 10 feet (3.0m) standard, Longer lengths optional |

| Machine Floor Space | 15 feet (4.5m) long x 44” (110cm) wide x 49” (122.5cm) high | 15 feet (4.5m) long x 51” (110cm) wide x 49” (122cm) high | 18 feet (5.5m) long x 73” (183cm) wide x 52” (130cm) high |

| Shipping Weight | 1400 Ibs. (636 kg), approximate | 3500 Ibs. (1588 kg), approximate | 6600 Ibs. (3000 kg), approximate |

| More | 210 Specs | 220 Specs | 233 Specs |

PHI 210 Synchro Bending Machine Specifications PHI 220 Synchro Bending Machine Specifications PHI 233 Synchro Bending Machine Specifications

Videos

PHI 220RH Hydraulic Tube Bender

PHI 220RH Hydraulic Tube Bender

PHI 210 Hydraulic Powered Semi-Automatic Tube Bender

PHI 230 Hydraulic Syncro Tube Bender

Tube Bender Terms: degree of bend (DOB), radius, wall, gauge, pipe size, tube size, wall, rotation, shape, round, elliptical, oval, draw, mandrel, torque, load, capacity, PLC, encoder, controller, HMI